Several rooms required walk-in accessible showers; no problem for On The Level. We formed the perfect a gradient in order for water to drain away quickly. We pre-sealed and waterproofed the modular wet floor systems which meant building up-stands around the perimeter so that the first 50 mm of the wall could be also waterproofed – for added peace of mind.

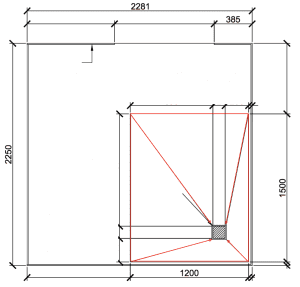

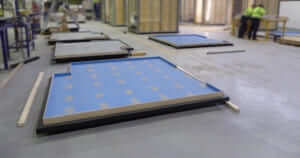

For this project we worked with over 20 different room configurations ranging in size from 2200mm x 2100mm to 2800mm x 2000mm. Working closely with our designers using CAD software we had to be accurate ensuring the ‘one piece’ floors were built within 1mm tolerance.

How do commercial clients benefit from using On The Level modular wet floor systems?

- Time saving. Our modular flooring systems arrive to your site ready to install and tile immediately!

- Less project management. Our clients generally contract their work out, using many different trades to help complete a job. When using On The Level, the pressure is taken off their workforce as we supply the complete floor area, which is then fitted into The floor is pre-tanked (waterproofed) and ready to tile as soon as it is installed.

How does the tanking process work?

Tanking, a way of waterproofing, is the method by which we use a flexible liquid rubber to seal and waterproof. The OTL Tanking system is a proven product, providing the client with 100% confidence of a leak free solution.

- Once the floor module (former) has been created and any imperfections levelled out, we apply our OTL liquid tanking solution to the product, – the tanking thickness once cured is 0.8 – 1.3mm.

- Specifically designed to prevent leaks in wet room areas, the tanking liquid rubber solution can be applied to several surfaces including timber, plasterboard, MDF, concrete screed and construction boards.

This project is a fantastic opportunity for the team here at On The Level. To work with such a prestigious client is a huge deal for us. The modular wet floors are manufactured and built within our Bedfordshire manufacturing facility, where our team communicate with various people including project managers, operations managers, and members of the procurement team for our client.