In the last 18 months they have gone from strength to strength with expanded premises and new models continuously being added to the range, all versatile enough for both Residential Park Home and/or Leisure Lodge Living. Each model comes in a variety of sizes, exterior and interior finishes and layouts and like On The Level, Sovereign are always flexible and happy to work on bespoke projects to meet individual customer’s needs.

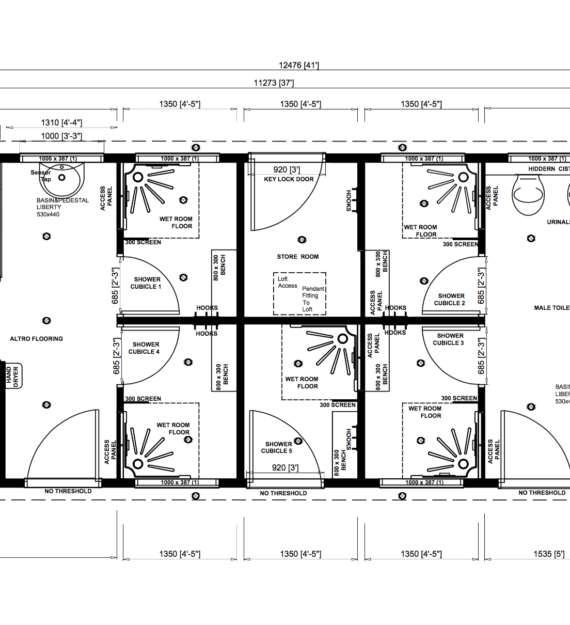

On The Level were commissioned to manufacture a complete floor system for a toilet and shower block which was built on a transportable chassis. The flooring system accommodated toilet and washroom floors, as well as sloping wet room cubicles and the complete floor area that OTL manufactured, was in fact 41 feet by 14 feet – a truly bespoke project! The final structure was then built upon this flooring system.

Paul Killpack, Operations Director at Sovereign Park & Leisure Homes Ltd, explains: “On The Level were originally suggested by our client for this project, but of course we still did a lot of product investigation and examination of the service they could provide before going ahead. We also shared our design ideas with the team at OTL and worked together on a final agreed design before finally placing the order.”

So what’s good about the quality of OTL products in Paul’s view, and what were our team like to work with?

“Manufacturing accuracy and tolerances were to a very high degree, meaning installation was very straightforward. The finish of the product prior to installing the wet room floor surface was smooth and even which meant that there was no additional prep-work required. The materials used for the flooring system were of a very high quality. The level of interest and enthusiasm in assisting us to scope and specify the solution and the support provided during both the design and build phases of the project was excellent. Being able to share CAD information and exchange solutions allowed both parties to maintain confidence that the result was exactly what was expected in terms of fit and buildability.”

James Clark, Managing Director of On The Level explains how the project unfolded: “Croft Farm Waterpark had previously used OTL to revamp two changing blocks with a total of 3 single showers and a multi shower complex. They were very happy with our work, so when they then had a new shower block being built by Sovereign Park and Leisure Homes they recommended us.

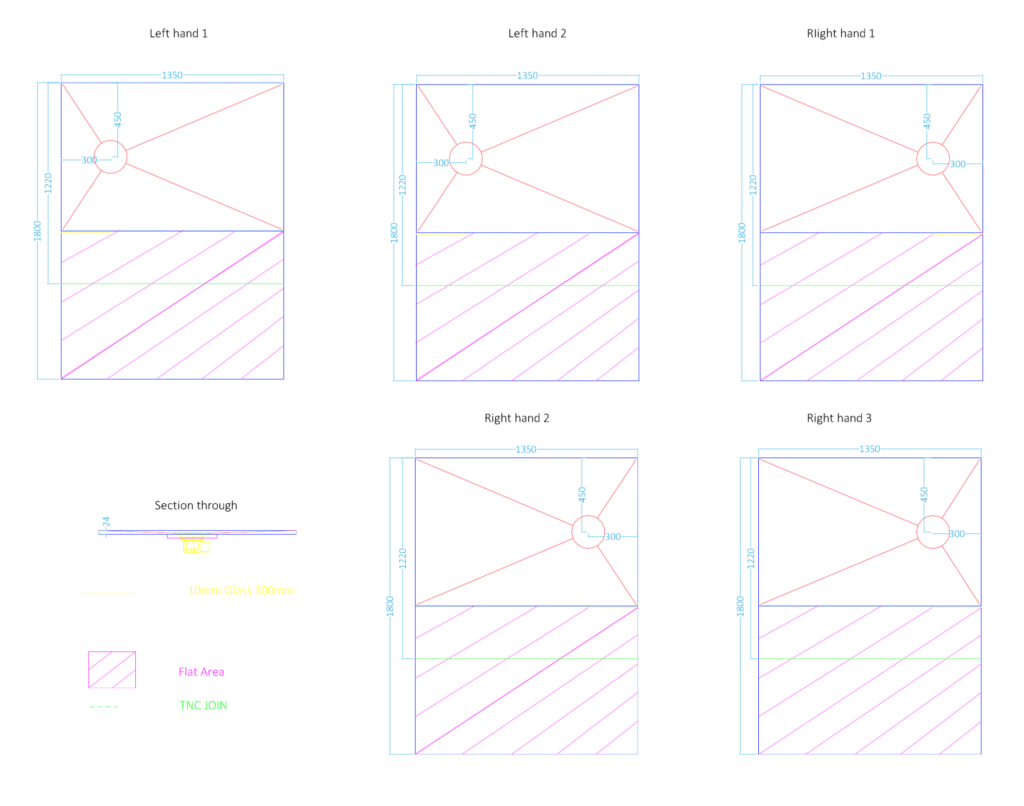

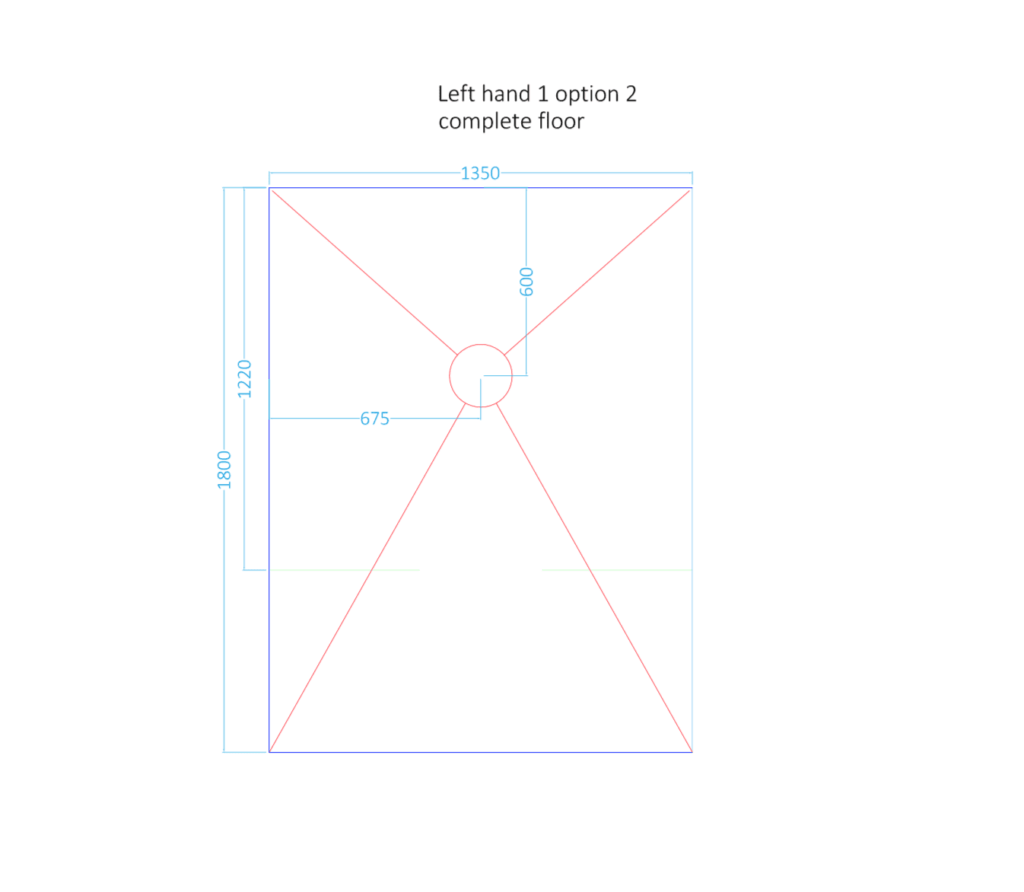

“The original drawing showed shower trays which were only a portion of the shower room – approx. 1350mm x 1000mm. Producing a former the complete size of the shower room made more sense however, as then it wouldn’t matter if water were to spray outside the showering zones, as the whole floor area would incorporate a gradient to the gully which could also be position to suit Sovereign’s requirements. After a conversation and design meeting with Paul at Sovereign it was therefore agreed that rather than OTL supplying only the 5 formers, we would produce the complete floor to the whole block. This would save a significant amount of time for the modular builders.

“We created a complete floor section of the same thickness, numbered for ease of installation. This was made up of 12 sections altogether and took just under 2 hours to install, ready for wall sections to be laid in situ to the flat section on the edge of the formers.”

Project summary

- Complete 12m x 5m flooring supplied in 4 working days on special order

- 24mm thick at perimeter edge (Standard Thickness)

- Locate wastes where convenient for customer

- Configure floor gradient accordingly.

- To the perimeter edge of the formers OTL had to make adjustment for a level area to which the timber stud walls could be mounted

- All floor components to site within 4 working days from order