With over 60 years’ experience, Premier Modular (part of global brand Waco International) is one of the UK’s leading suppliers of modular building solutions, working alongside the world’s biggest construction companies on some of the country’s most prestigious projects. Premier have a proven track record in delivering a high standard of modular buildings quickly and efficiently using cutting edge British manufacturing techniques. Major commercial projects include The British Museum, Westfield Shopping Centre, Battersea Power Station, Stansted Airport and many hospital and university contracts including Manchester University and Norwich Community Hospital and several large Ministry of Defence projects including Project SLAM, the subject of this On The Level case study.

This construction phase of a £1.2 billion project to improve the living accommodation of single service personnel has just completed after 12 years. The single living accommodation modernisation project, better known as Project SLAM, has been one of the largest new build and refurbishment projects in the UK and has delivered successful renovations and constructions on 52 locations from Scotland to Cornwall. 121 separate projects have improved or created more than 22,000 bed spaces in this time.

Premier Modular designed, manufactured, delivered and installed 8 accommodation blocks (all on time) to 4 RAF bases throughout the UK, 600 modules altogether, and On The Level were initially contracted to produce standard 1000mm x 1000mm formers. These would then be built into a volumetric modular build which would be tanked / waterproofed onsite then tiled directly over.

As this was a volumetric modular type build one of the most important factors was ‘time on the production line’, as OTL’s Mark Crabtree explains:

Time is money for sure when it comes to modular building. Using a standard 1000mm x 1000mm former would have made installation that bit much more time consuming. Cutting a standard former to the correct size and also tanking / waterproofing the bathroom on the line is very time consuming and also relies upon the contracted workmen’s ability to complete the tanking procedure correctly.

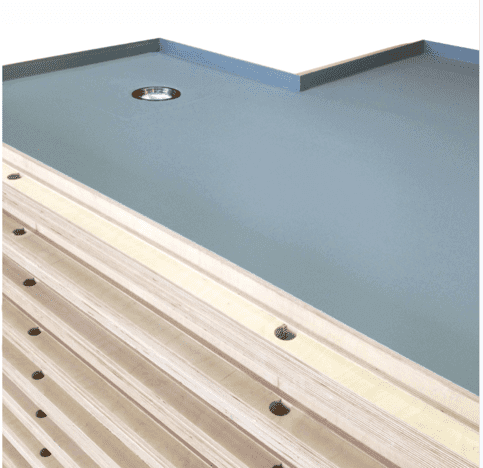

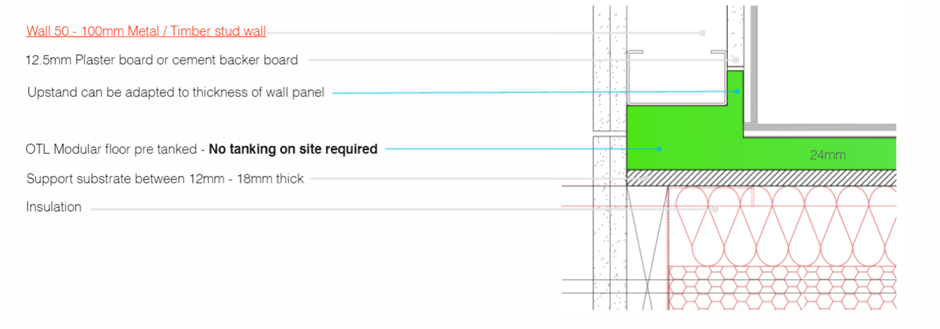

The Solution was that On The Level designed a completely bespoke new product for the project, creating a 100% waterproofed bathroom floor which incorporated the floor gradient for a level access shower. The gully was also installed by OTL and professionally tanked / waterproofed at OTL’s production facility so that there was no need for any tanking to be carried out onsite by the client.

On The Level also made a complete mock-up of the modular floor and tested it fully before supplying anything at all to Premier Modular. As Crabtree stresses:

We are incredibly proud of our reputation and the quality of our workmanship, so it is important that we always test to ensure we are able to provide our 100% watertight guarantee.

Peter Chadwick, Commercial Manager at Premier, recalls how he first discovered On The Level more than 10 years ago, following an online search for a reliable and reputable wet room former manufacturer with the highest levels of product quality, for a project he was working on at the time.

Peter explains why he has kept coming back to OTL over the years since then:

I really like their very versatile timber former products. It’s quite bespoke what we do and that’s what they are great at – bespoke products for specific projects, even for large scale multiple unit contracts like the latest stage of the Ministry of Defence SLAM (Single Living Accommodation Modernisation) initiative – this project that we’ve worked on together.

Chadwick summarises

On The Level’s products are excellent and their service outstanding.

Advantages to Modular wet floors

- Pre sealed / waterproofed in OTL factory by expert tanking professionals

- Wall upstands to perimeter floor edges – this provides a 100% watertight seal where floor meets wall intersection

- Floor can be made to any shape or size bathroom configuration

- Supplied with 100% watertight guarantee

- Acceptable for Electric and Water underfloor heating

- 24mm thick with option for 30mm thick

- Fast delivery for quantities over 100

- 1 in 5 modular floors are flood tested before leaving the factory

Key Advantages to the customer

- No drying times for tanking to cure

- No need to rely on inexperienced labour onsite to tank correctly

- Tileable straight away

- Pre-formed gradients in floor to incorporate level access showers

- 85% time saving over installing individual components

- All flooring products are FSC® certified.