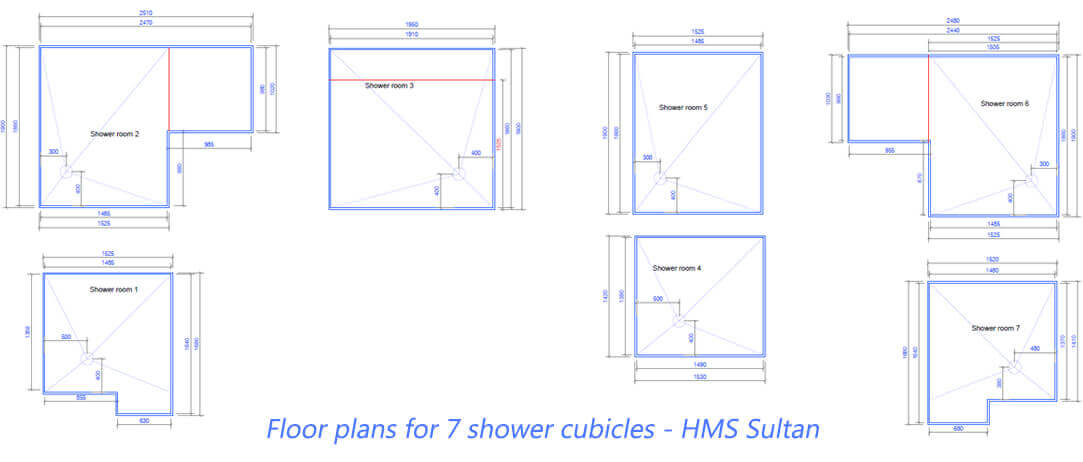

The video below shows the shower rooms on one of the floor at the beginning of the project, once the old systems had been removed. The next graphic shows the floor configurations for each of the 7 shower areas.

Following an initial consultation with MRA, our resin floor formers were specified, forming part of the main contractor tender. Martin Ralph were new to On The Level so we helped them to better understand the features and benefits of using a specific wet floor system, in particular with the preferred floor finish – resin.

The successful contractors were Concept Building Services (Southern) who subsequently got in touch with us to discuss the refurbishment programme at the HMS Sultan base in Gosport.

Our systems were also new to the contractor so we visited the site to assist with the primary survey, taking into consideration any site restrictions and existing gully locations as well as each shower room size and configuration, so that we could accurately calculate the falls for efficient water drainage.

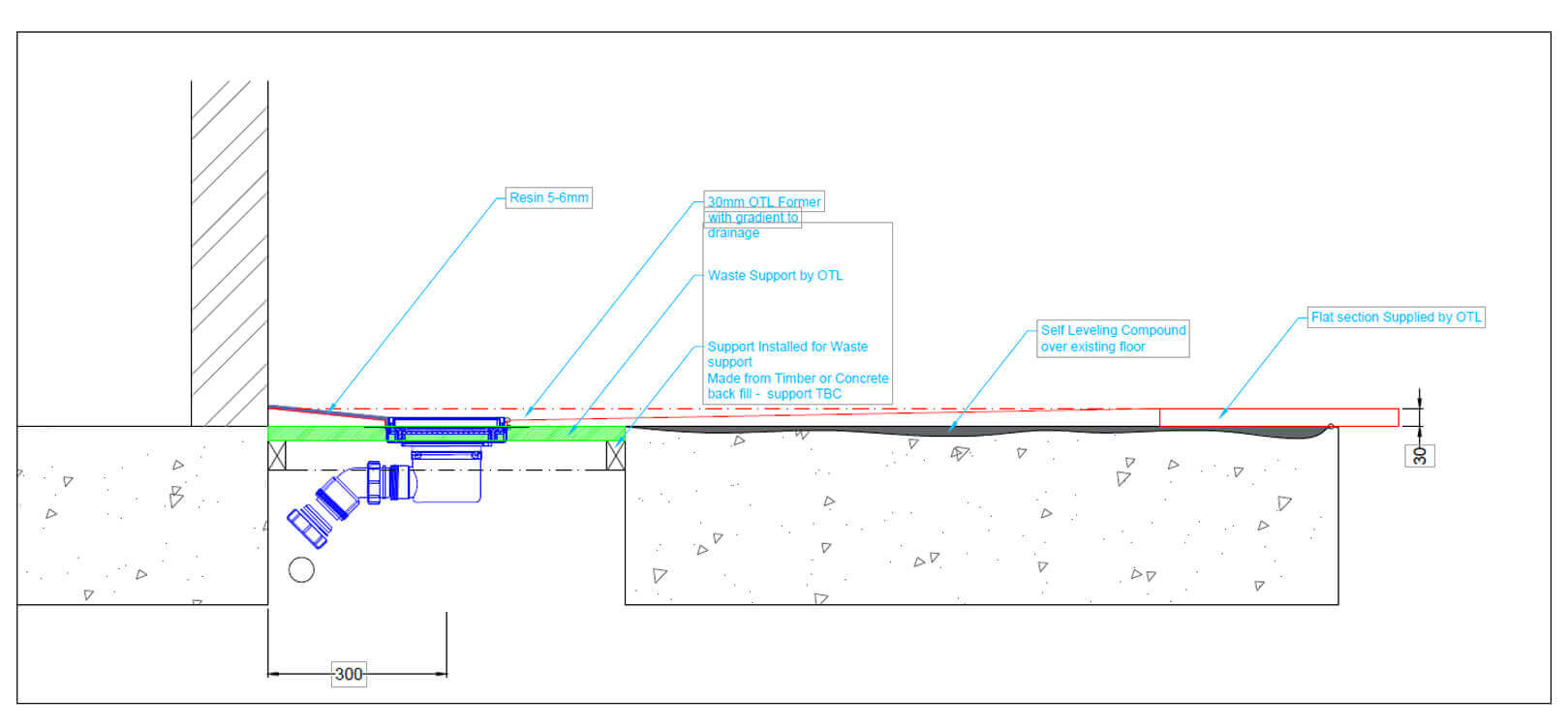

The diagram below shows an example of how the floor build up would incorporate our former.

This early engagement with the contractor allowed us to work together and provide them with peace of mind that the shower floors would be made to exact site requirements. It was agreed that the project would be delivered in three phases;

Phase 1 – the 2nd floor showers

Phase 2 – the 1st floor showers

Phase 3 – the ground floor showers

Following the installation of a full waste support and formers, an epoxy resin floor was applied by Euro resin Solutions, with a square solid stainless steel grate supplied by OTL.

Jason Ralph, Associate at MRA had this to say about the project:

OTL provided very useful technical advice during the early design stages. The OTL resin formers provide us with confidence that water will be efficiently removed from shower areas and take the headache away from contractors trying to create their own falls. The team continued to support the project with site visits to ensure that the contractor prepared and installed the floors correctly prior to the resin floor being applied. We have since specified OTL for more similar type projects.